9 common misconceptions about stainless steel weld cleaning machines

A rise in health and safety concerns has meant stainless steel fabricators are looking for alternative stainless steel weld cleaners from aggressive pickling paste. Electrochemical/electrolytic weld cleaning machines are the latest trend in weld cleaning, with claims of providing a safer, quicker and better alternative to pickling paste.

We talk to a LOT of stainless steel engineers who don't want the hassle of pickling paste, but are not too sure about taking the leap into investing in an electrochemical cleaner. Below are 9 of the most common misconceptions we find in talking to them...

1. They're really expensive

So without getting into too much detail, lets consider the following factors in terms of cost:

- What price can we really put a price on health and safety of ourselves and our staff?

- The average ROI for a good quality electrolytic weld cleaning system is only 5-6 months.

- A good machine will eliminate all need for pickling paste, saving you time and money on protective equipment, clean up processes, and health and safety compliance measures.

- You'll be producing much better, cleaner, longer lasting stainless steel products, so your customers will be happier!

- Did we mention it's safer, quicker and better than pickling paste?

Ok, so you're still thinking investing $5k+ for electrochemical cleaning stainless steel is a big step. And to be honest you're still not quite convinced these electrocleaning systems will do everything they claim they will do. You might have even tried one of these machines in the past and found it wasn't up to the job....you're not alone.

The best advice we can offer is to ask suppliers for customer testimonials of their product, and for a free trial in your workshop. Test the machines on the toughest jobs you have, and see for yourself if electrochemical weld cleaning is an investment worth having in your workshop.

2. They work, but are too slow

This may have been true of the machines of the past, or inferior models, but a good electrochemical system will work faster to clean the weld than traditional pickling paste - and that's just cleaning the weld.

On top of that, you also save time from:

- No need to gear up with all the PPE required for pickling acid

- Cleaning can be done without having to move the job

- No need to dismantle the product to get into tight spaces

- Clean-up is just neutralising and a wipe down!

3. Can't get into tight spaces / Won't work on small jobs

Good electrochemical weld cleaners use a brush instead of the chunkier solid tips of the past. Brushes not only work better at cleaning the weld and removing tints without scratching, but they work to reach into those tight nooks and crannies.

Be warned, this is something that can differ between machines, so you will need to check to make sure the brushes available will work for the welds you need to clean. Try before you buy, and get suppliers to let you test the machine in your workshop, on the typical welds you'll be cleaning. For example, Cougartron system offers a wand with a twisting shroud that allows you to choose the length of your brush, providing more control, and and increased brush life of up to 100%. Read more here.

4. The vapours produced from the machines are dangerous - keep away from it!

It's always good to be cautious, especially when you're used to the dangers of pickling paste, however the smoke that comes from most electrolytic weld cleaning systems is quite safe.

The low concentration of weld cleaning fluid, coupled with heat and water produces steam/smoke that comes off during the cleaning process. This smoke is actually 80% water vapour and is not a health and safety risk when used in a well ventilated area. In confined spaces a disposable mask (P2) is sufficient filtration for thermally generated particles (steam/smoke).

For more detailed information, check out our blog: What You Need To Know About Electrochemical Cleaning Fumes

You can also download the MSDS here which also advises on PPE requirements for general handling of weld cleaning fluid used with Cougartron weld cleaning systems. Be sure to check the MSDS sheet of the specific weld cleaning fluid recommended for individual machines before purchase.

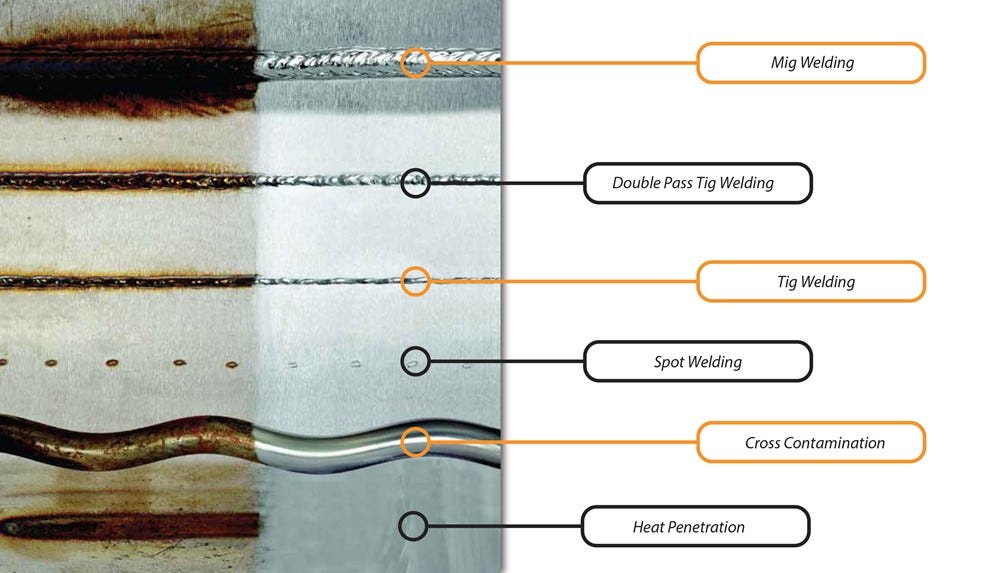

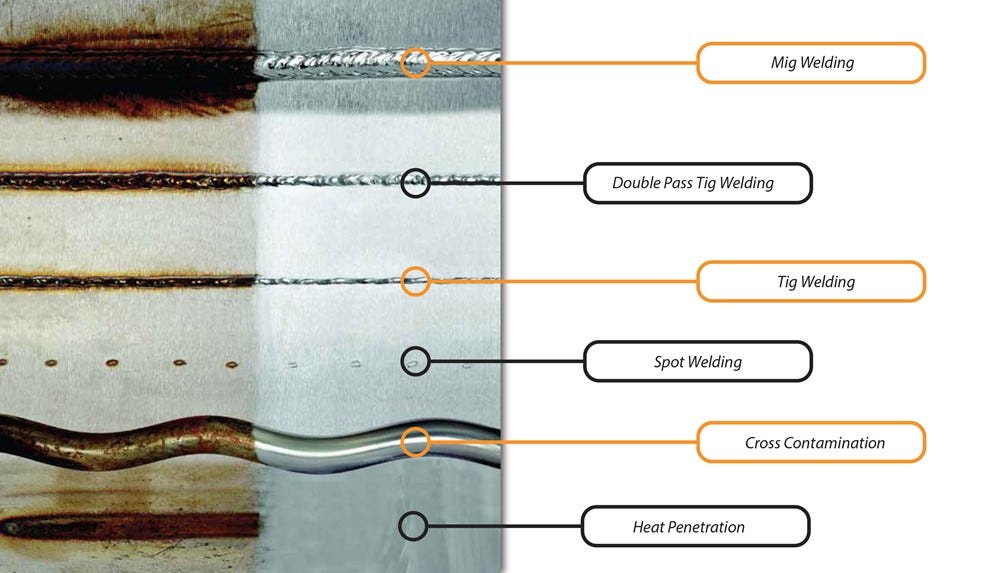

5. Electrolytic weld cleaning machines only work on TIG welds

This certainly shouldn't be the case for any decent powerful European electrolytic weld cleaner! A good machine will have the power to clean and polish the most rugged MIG and TIG welds. See our image below:

Here's what Phil Reid from Singh's Engineering, Hamilton has to say about his experience using the Cougartron ProPlus weld cleaning system > Electrochemical weld cleaning review

6. The brushes and cleaning solutions don't last long and are expensive to replace

Not all weld cleaning systems work the same, and unfortunately some systems can offer a cheaper, lower power initial product which is subsidized by a higher cost and more use of consumables. Also some machines use a pump to administer the cleaning solution rather than manual application. While this seems convenient, it actually ends up using a lot more cleaning fluid than what is needed, resulting in waste, mess and unnecessary costs. A good machine will allow you to dip the brush into the solution so you can only apply what is needed, reducing waste, and providing a better cleaning result.

2L of cleaning solution should clean approximately 150m of weld. For a good machine the average life expectancy of brushes are:

- TIG welds: 60-80 hours

- MIG welds: 55-65 hours

- Stick welds: 40-50 hours

The Cougartron system offers a wand with a twisting shroud that allows you to choose the length of your brush, providing more control, and and increased brush life of up to 100%.

7. The surface left after cleaning is cloudy

If the stainless steel surface is left looking "cloudy" or with a matt look finish after electrocleaning, then you may have a lemon machine. A good electrochemical weld cleaner should leave the stainless steel with a microscopically smooth surface that is surgically clean. While electrocleaning does not scratch or polish the surface, a good European machine will have a polishing function to enable a higher level of polishing when required.

Watch this video of the Cougartron ProPlus in action >

8. Electrochemical weld cleaners do the same job as electropolishing baths

Sort of, but not really. While both techniques use an electrochemical process to clean metal, electropolishing uses a bath to soak items in a cleaning solution and applies an electric currant to clean and polish. An electochemical cleaning machine also uses a cleaning solution and electric currant, however the solution is applied directly to the area being cleaned. These machines are small and compact, so can be taken to the job, compared with electropolishers where the job will need to be moved to go in the bath. Also where electropolishing provides one overall function, a good weld cleaning machine can adjust the power output to suit the work surface, and will provide a cleaning, polishing, and in some cases, etching function.

9. Electrochemical cleaning machines are for workshops that do a lot of weld cleaning

We get quite a few engineers who feel they can't justify the cost of a stainless steel weld cleaning machine because they don't do enough weld cleaning. While this is completely understandable, the fact is, if you have to do ANY weld cleaning, having an electrochemical weld cleaning machine WILL save you time and money compared with pickling paste. Benefits you'll see include:

- Quick and easy set up when you do need to weld clean stainless steel

- Compact and portable - take the machine wherever you need it either around the workshop or off site

- No need for aggressive and dangerous pickling acids

- Less risk to health and safety

- Reduced requirements for PPE and WorkSafe regulations

- Quick and easy clean-up

If you don't do a lot of weld cleaning you may not need the most powerful machine with all the bells and whistles, but you'll still want something that will do the job well. Ask suppliers if they have a machine that will suit your needs. Just make sure it is powerful enough to do what you need it to!

We hope this blog has helped clear up some of the ideas you may have heard or experienced in the past with electrochemical cleaning systems. Hear what some of our customers say about their experience using the Cougartron ProPlus here.

Need assistance?

Need assistance?