How to check a powered air respirator before each use

Like any item of protective equipment, your powered air respirator should be tested to make sure it is working correctly before each use. After all, you don't want to end up in a cloud of dangerous welding fumes before finding out something's not quite right! Here's a quick run through of how to self check your PAPR before each use...

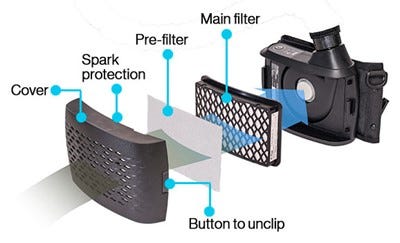

Blower Assembly

Make sure the spark screen, pre-filter and particulate filter are properly installed and securely attached.

Breathing Tube

Make sure the breathing tube is not damaged and the connector is locked to the blower unit and helmet.

Battery

Check the connection to blower unit is secure, and battery is fully charged.

Face Seal

Inspect the face seal for damage and replace if necessary. Make sure the air is being supplied to the helmet.

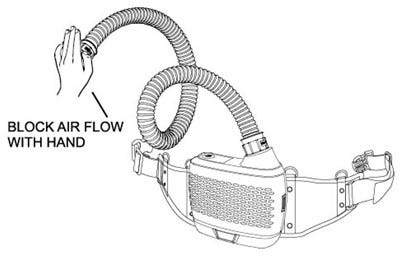

Alarm Sound Check

Make sure the filter is equipped and the battery is fully charged before doing this test.After turning on the unit, check the alarm sound warning function by blocking the air outlet as shown below. The warning signal on the panel should flash with a sound and blower will vibrate (approximately 15 to 30 seconds after the outlet is blocked). The unit is working correctly if the warning functions follow the process above.

Airflow Rate Test

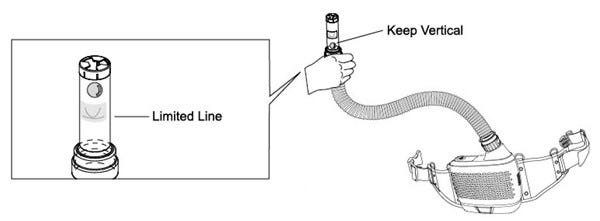

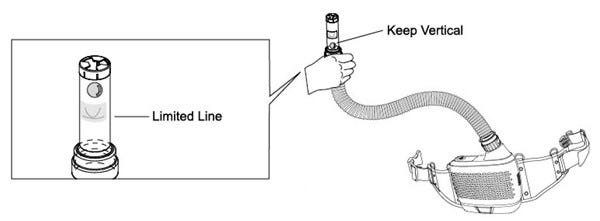

Make sure all the components are fully assembled before testing.

Connect the end of the hose to the bottom of the airflow indicator and then press the start button. Keep the flow indicator vertical.

If the ball inside the pipe is floating above the limited line in low speed mode, then the unit is working correctly.

If the ball cannot float up to the limited line, refer to our Trouble Shooting Guide here

When to take action

If any of the following conditions occur, you should exit the contaminated area immediately. Only remove the respirator once you are outside of the contaminated area/workshop.

- If any problems are shown on any part of the unit (eg. the air supply has stopped or the amount being supplied has decreased)

- If it becomes hard to breathe, you are feeling dizzy, get a headache, or can smell or taste fumes/contaminants.

- If you suspect contamination levels within the workshop are too high for the respirator to provide protection. NEVER use in a workshop with too high level of contamination.

Need assistance?

Need assistance?