How to select the right brush for metal fabrication

Wire brushes are great for removing coatings from the metal surface, without damaging the base material. They're also a lot more flexible than bonded or coated abrasives, making them ideal for cleaning hard to reach areas. If you're in the market for a wire brush, but not sure which kind you need...keep reading, and we'll give you a hand.

Wire brush or abrasive?

Wire brushes are used as an impact tool to remove oxide, paint or other adherence from the surface of the metal, without damaging the base material. Hard abrasives are used when you are wanting to remove the base material as well as the surface adherence.

Wire brushes are much more flexible, allowing you to clean hard to reach areas, and adapt to uneven surfaces, which bonded and coated abrasives can not.

Which brush is right for the job?

The selection of the right type of brush depends on the type of finishing required (fine or coarse), and the characteristics of the surface to be brushed (stainless steel, carbon steel, wood etc...).

Besides that, in the case of the brushes fixed in a machine, it is necessary to know the main features of the machine in order to choose the right brush type:

- The maximum diameter allowed.

- The machine speed or RPM.

- The arbor hole diameter or the thread type (M14, 22mm, etc...)

| MACHINE Normal Speed |

MOST COMMON BRUSHES | BRUSH DIAMETER |

| Bench Grinders | Crimped & Twist Knot Wheels | 75mm - 250mm |

| Large Angle Grinders (5,000 - 8,500 RPM) |

Crimped & Twist Knot Wheels | 100mm - 150mm |

| Crimped & Twist Knot Cups | 75mm - 125mm | |

| Small Angle Grinders (10,000 - 12,500 RPM) |

Crimped & Twist Knot Cups, Bevels & Wheels | 65mm - 115mm |

| Drill & Pneumatic Tools (15,000 - 20,000 RPM) |

Wheels & End Brushes with Shank | 25mm - 100mm |

Crimped Wire Brushes vs Twist Knot Wire Brushes

Crimped wire brushes are excellent when working on uneven surfaces, when you want to obtain a regular or fine finish, due to their higher flexibility.

Twist knot wire brushes are better for removal applications. They offer a longer life, and higher removal capacity, but will give a rougher finish.

Wire Diameter

When working with wire, the gauge of the brush determines the type of finishing you will achieve. A thicker wire will provide a more aggressive brushing action, where thin wire will produce a finer finish.

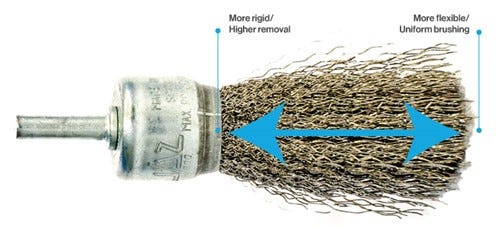

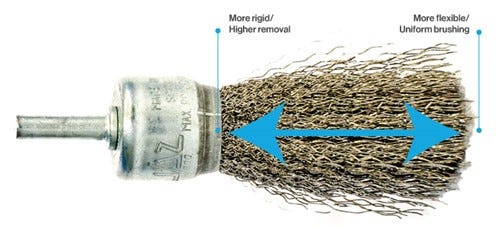

Trim Length

The shorter the trim length, the more rigid the brush will be, which is better for removal. As the trim length gets longer, the brush becomes more flexible, providing a more uniform brushing on both even and uneven surfaces.

Types of Wire

Brass Coated Steel

- High performance and flexibility

- Anti-corrosive material

- Suitable for a large range of finishing

Steel

- Suitable for twist knot brushes

- High removal capacity

- Not suitable for stainless steel surfaces

Stainless Steel

- Used for brushing stainless steel, aluminium and non-ferrous metal surfaces.

- Slightly magnetic

Best Practices for Brushing

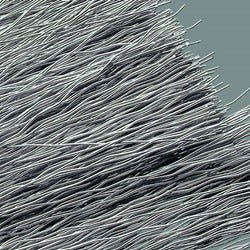

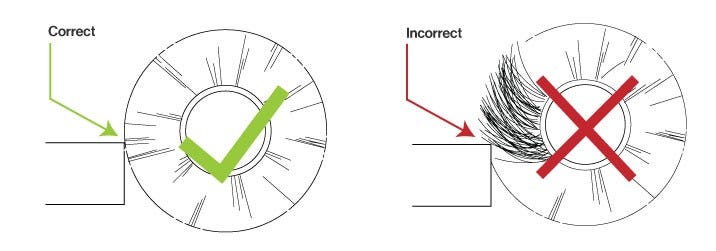

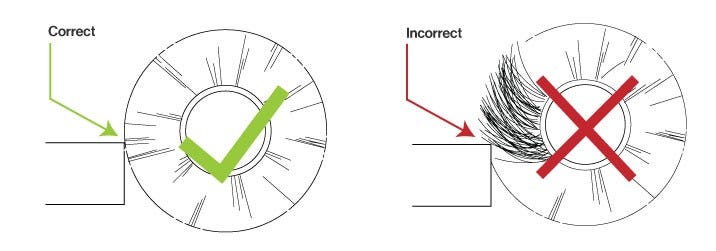

When using a wire brush, it should always be the end of the wire that brush against the material surface.

If too much pressure is applied, this can cause the wires to over-bend. Over-bending will make the wires weak, leading to premature breaking - so the working life of the brush will be greatly reduced.

For jobs that require a high removal rate, rather than adding pressure to the brush, best practice would be:

- Use a more aggressive brush - twist knot, with thicker wire and a shorter trim length.

- Increase your brushing speed - use a brush that can work faster or that has a bigger diameter, such as a wheel brush.

Working Angles

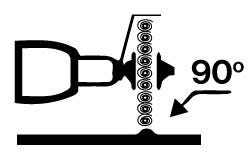

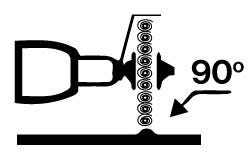

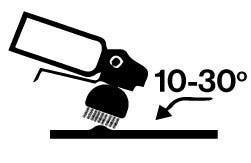

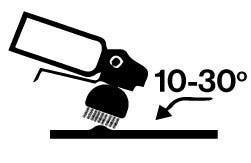

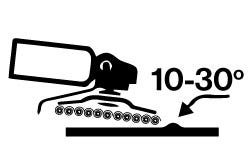

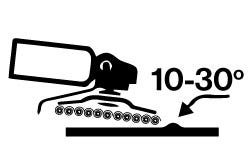

Wire wheels and brushes should be used on an angle to the work piece. The optimal angle will depend on the brush characteristics, the power tool being used, and the application. Further to this, the brushing pressure and technique will impact the outcome. Here is a general guide:

Twist Knot Wire Wheel Brushes

Wire Cup Brushes

Twist Knot Bevel Brushes

RPM

The power tool speed influences the performance of the brush and the safety of the operator. If the load speed marked on the power tool is higher than the brush maximum RPM, do not mount the brush. maximum RPM are indicated on the brush side plates, and should never be exceeded. These are the maximum RPM the brush can run with no work applied (spinning free). It is merely a safety indication for the user - not the recommended operating speed.

Need assistance?

Need assistance?