Operational & Safety Instructions for Coated Abrasives

Coated abrasives such as flap discs & wheels, linishing belts, and sanding discs are simple enough to use, but there's still things you need to be aware of to make sure they're used correctly - after all, ANYTHING used with a power tool can be dangerous. Here's some general instructions on how best practice for the use of coated abrasives..

Coated abrasive products can generate dangerous situations and/or create accidents if not used correctly . The following instructions and the indications on the product and labels are important for anyone operating coated abrasives:

- Operators must be instructed on the use of abrasive products, comply with the laws and decrees of their country and the safety operating instructions of the grinders on which abrasive products are mounted.

- Do not allow untrained or incompetent operators to use abrasive products, and always handle and use them with care.

- The use of damaged products, inadequate mounting and use can cause accidents, damage and serious injuries to people.

- Grinding and polishing applications can release hazardous contaminants in the air, so the use of appropriate powder/fumes suction systems and respiratory protective equipment is essential

Expiry:

Coated abrasive products have no expiry but we suggest they are used within 3 years from the manufacturing date.

Checking, transport, handling and storage:

- Always inspect packaging for damages and refuse shipment if any is identified.

- Handle with care, avoid shocks, and store at temperatures between 10°C/30°C and relative humidity at 45% to 65%.

- Do not expose products to frost, water or chemical products such as solvents.

- FIFO - First in, first out - Always use the oldest products first.

Wheel inspection:

- Before mounting, make sure that the product is not cracked or damaged.

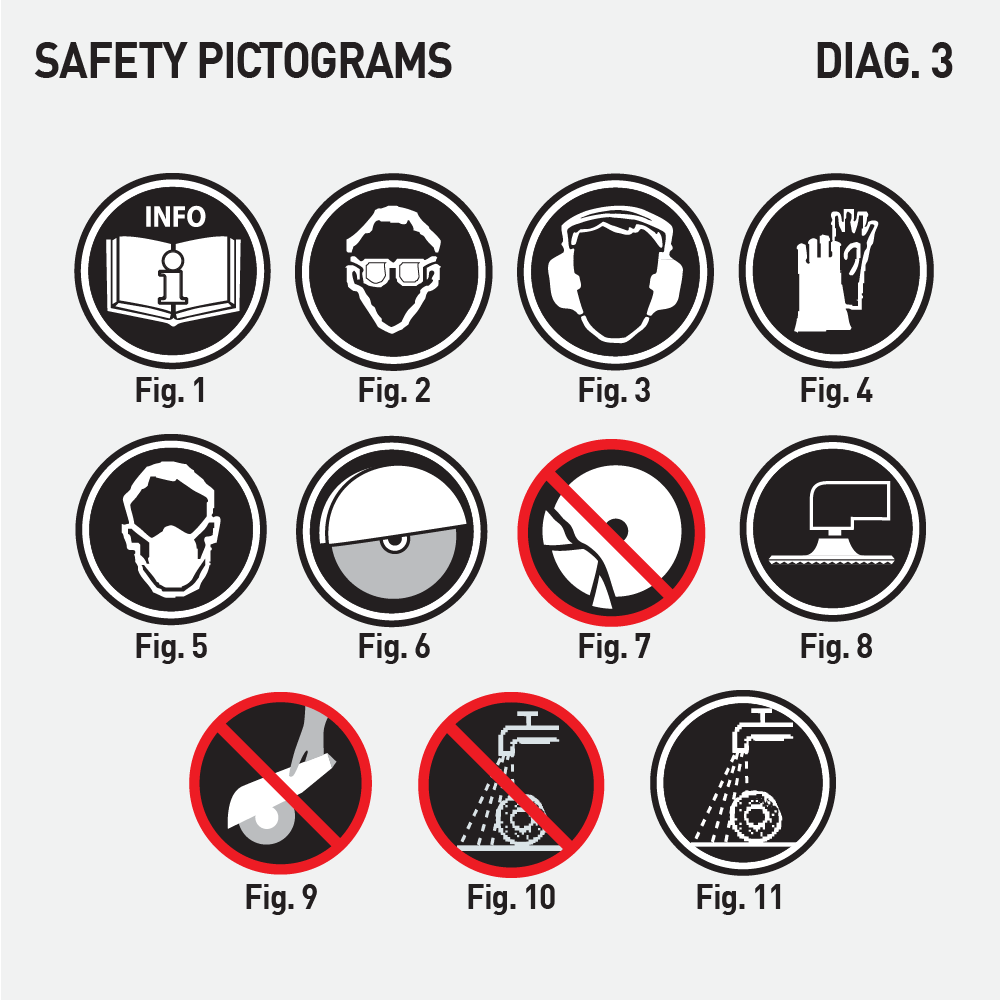

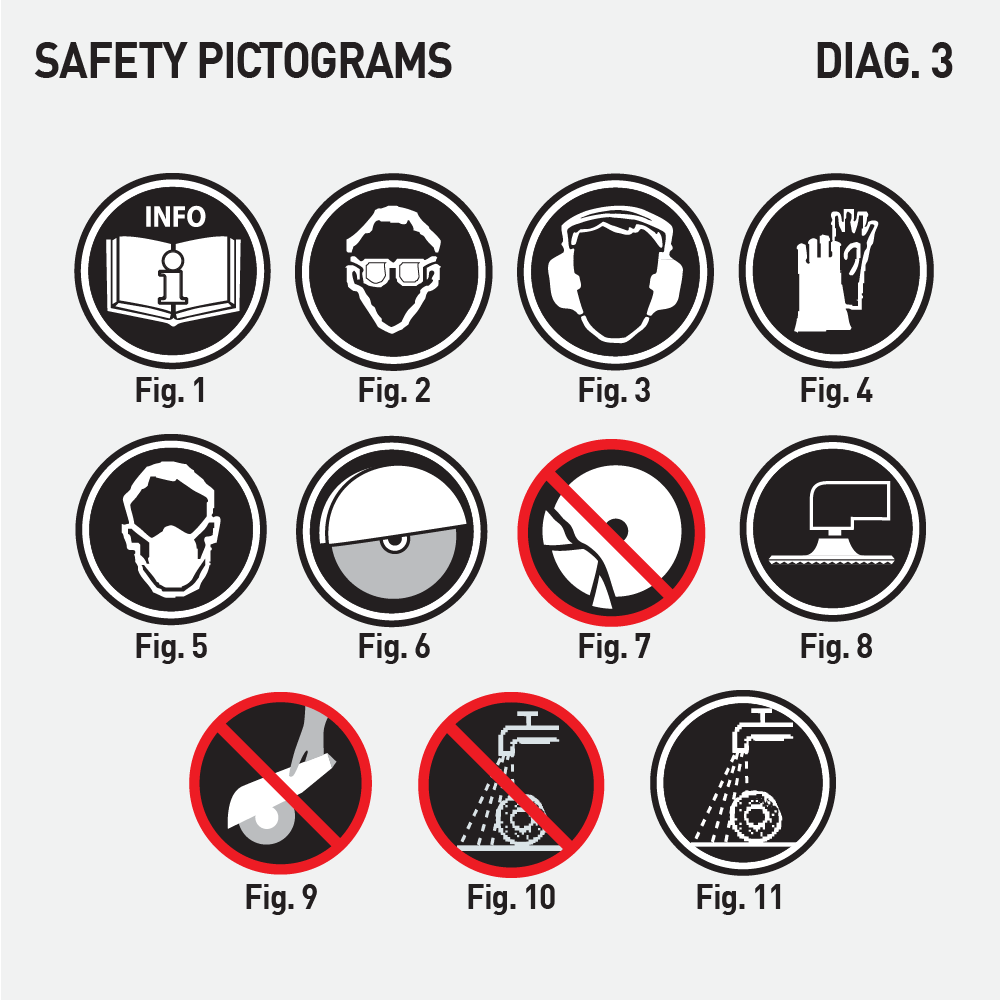

- Do not use damaged products (DIAG.3 fig.7).

Grinder inspection:

- Check flanges, backing pads, support pivots and adapters.

- Make sure the grinder and the product to mount are compatible and suitable for the type of work to be done.

- Always use with the safety guard supplied with the grinder (fig.6) and always direct the open part of the safety guard to a direction opposite the operator.

- Grinders should be regularly inspected and maintained.

Eyes, face and body protection:

- Always use eye and face protection such as mask, screen and glasses (fig.2), hat or head protection, protective clothing, and safety shoes.

- The noise generated by coated abrasive products can exceed 80 dB, meaning prolonged exposure can cause permanent damage to hearing. Use ear protection such as earplugs and anti-noise screen (fig.3).

- The vibrations generated by coated abrasive products can cause damage to the human body so make sure you adopt work turnovers and resting breaks.

- Carry out a specific evaluation of the noise and vibration risk and adopt suitable protection and precautions.

- Wear protective gloves that fully cover wrists (fig.4).

- Carry out an evaluation of the physical and chemical risks associated with the use of abrasive products and adopt suitable precautions and protective measures.

- Protect the respiratory tract by wearing a mask with specific filters or air respirator systems.

- Use protective measures of the working environment such as ventilation, filtration and powder/fume suction systems (fig.5).

- Nearby personnel must be protected with all the above precautions/measures.

Assembly instructions:

- Follow the assembly instructions supplied with the grinder and the use restrictions shown on the abrasive product label (fig.1).

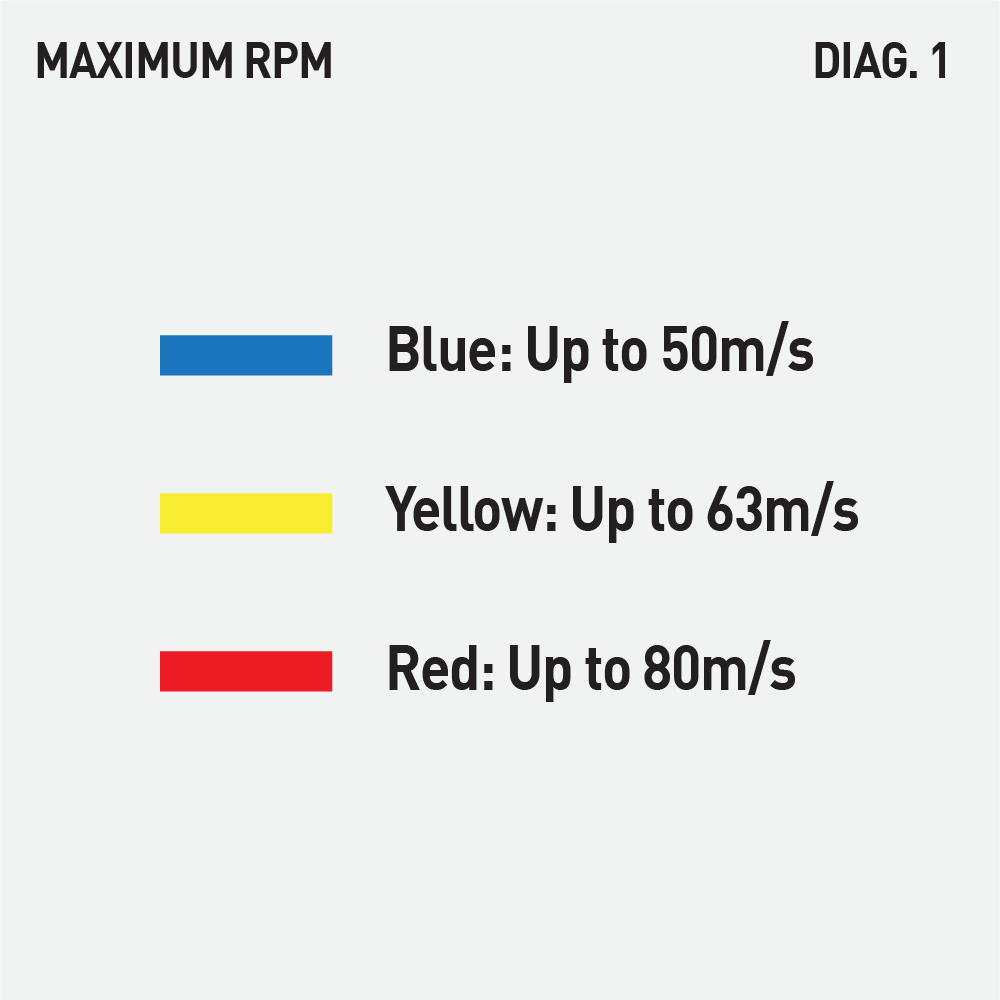

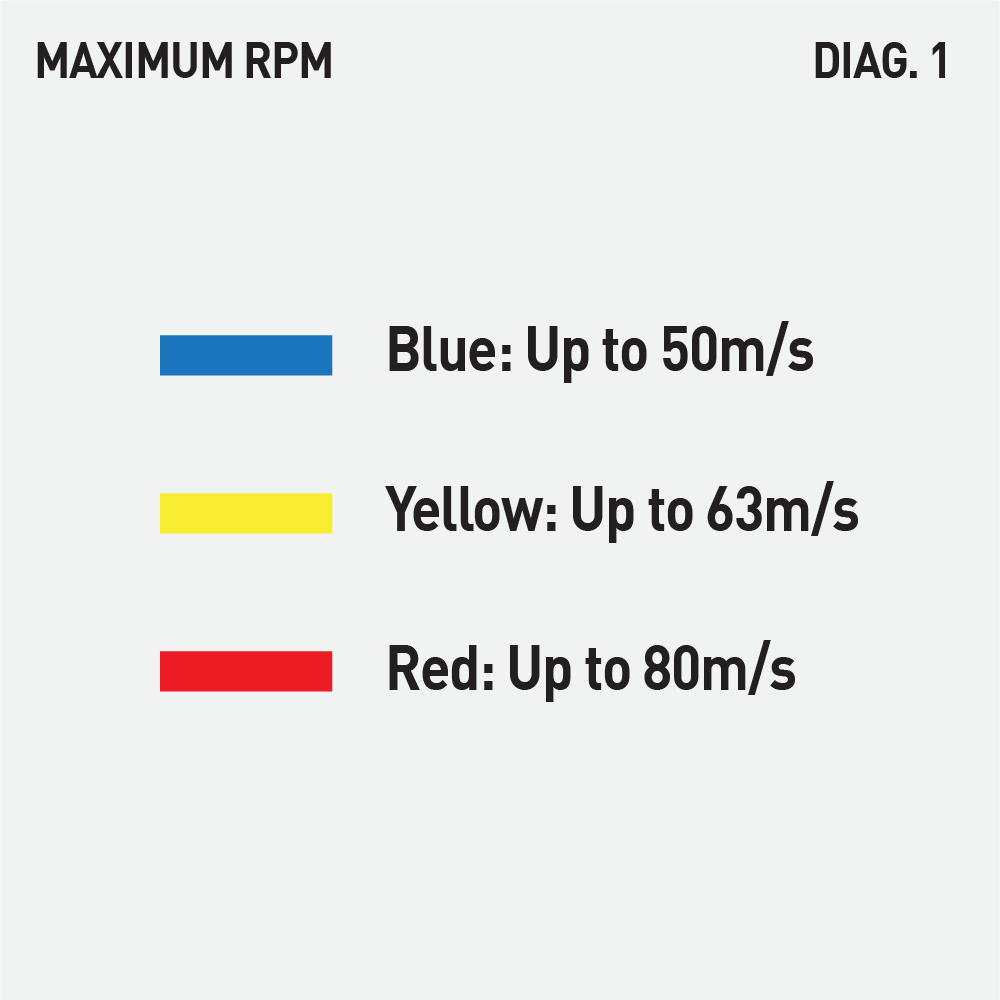

- Make sure the maximum turning speed (RPM) of the grinder is always (in any operating condition) lower than or equal to the speed shown on the abrasive product label (DIAG.1 ):

- For abrasive belts, make sure the peripheral speed of the driving rolls of the grinder are lower than or equal to the maximum speed allowed for the type of belt.

- Make sure that the dimensions and shape of the abrasive product correspond to those allowed for the grinder.

- Check that the abrasive product is wholly contained within the safety guard of the grinder. Do not modify the clamping flanges.

- Before mounting or dismounting an abrasive product, disconnect the power supply (electric energy, compressed air, etc.).

- Do not force during assembly.

- Avoid clamping with too high tightening torque. Once the product is installed, make sure that it rotates freely by turning it by hand before starting the grinder.

- Check the presence, correct installation and securing of the safety guard.

- Connect the power supply, start the grinder and make it turn for at least 30” before putting it in contact with the working piece.

During this test, do not keep the open area of the safety guard oriented towards the operator and other surrounding personnel. In case anomalies, vibrations, irregular rotation should occur, let the grinder stop naturally, disconnect power supply, remove the abrasive product and check its assembly. If the problem persists, reject the product and inform the supplier of the problem.

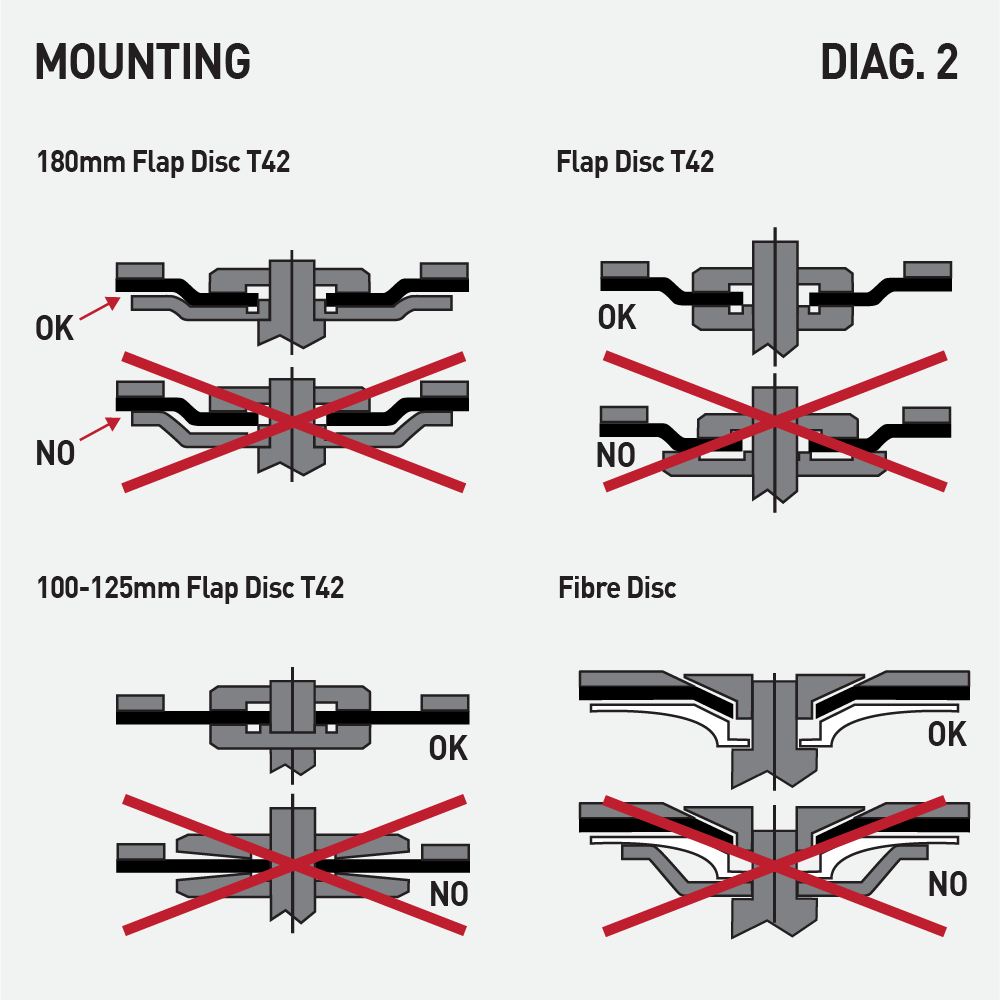

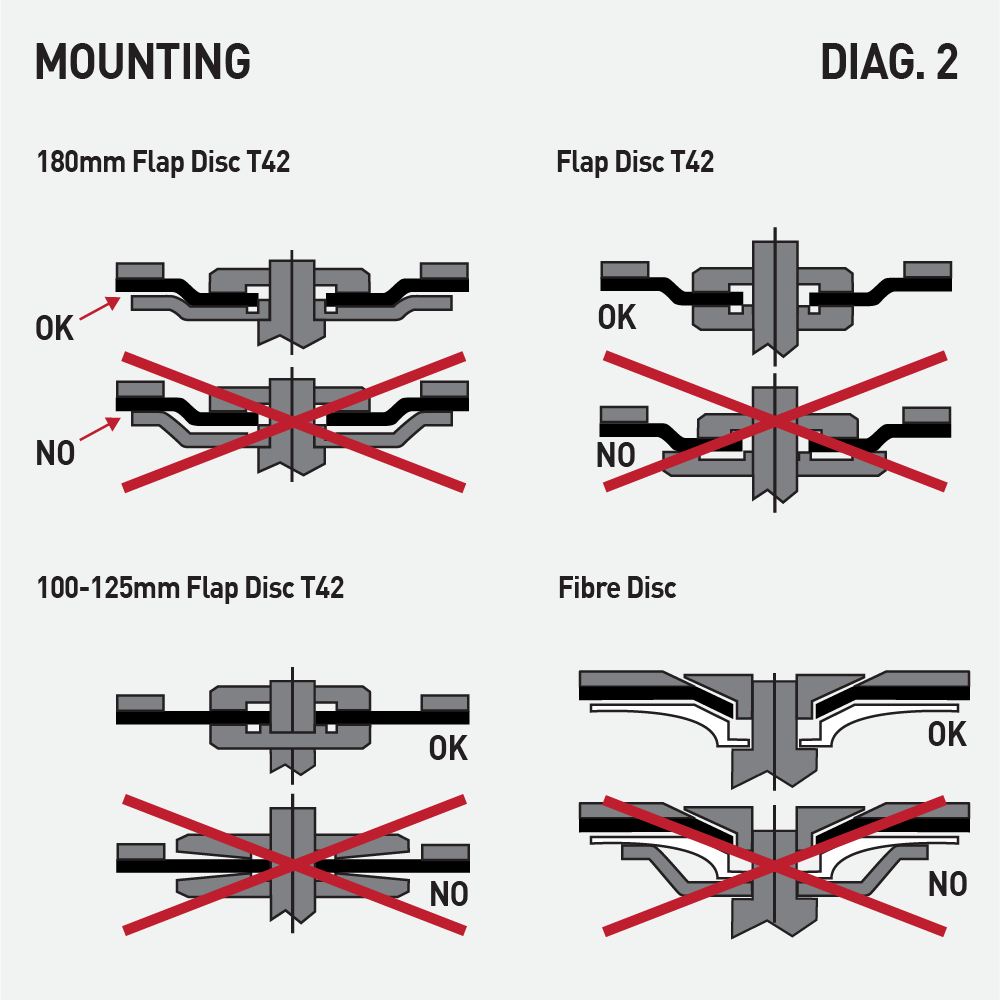

Clamping flanges:

- Make sure the flanges are flat, clean and smooth.

- Always use suitable flanges (DIAG. 2).

Instructions on product labels:

Specifications characterizing the product: dimensions; type of abrasive (A, Z, C); Size of abrasive grit (P16-2000).

Maximum allowed turning speed (RPM) and maximum allowed peripheral speed (m/s): the most common peripheral speeds are 30-63-80m/s.

Eu Reference norm: EN13743

Indications on the workable materials: steel, aluminum, cast iron, stainless steel, stone, marble, etc.

Pictograms (DIAG. 3): from (fig.1) to (fig.7) explained above; (fig.8) only permitted with backup pad (for sanding discs); (fig.9) do not use on portable grinders; (fig.10) not suitable for wet grinding/polishing; (fig.11) only suitable for wet grinding/polishing.

Use instructions and restrictions:

- Use the coated abrasive products only and exclusively on materials, purposes and grinder types they have been designed for.

- Grind/polish progressively, slowly and delicately.

- Do not apply too much pressure and do not grind pieces subject to forces or pressures that could be released due to this operation.

- Remove all combustible, flammable or explosive materials from the working area. Firmly fix the work pieces before starting to work.

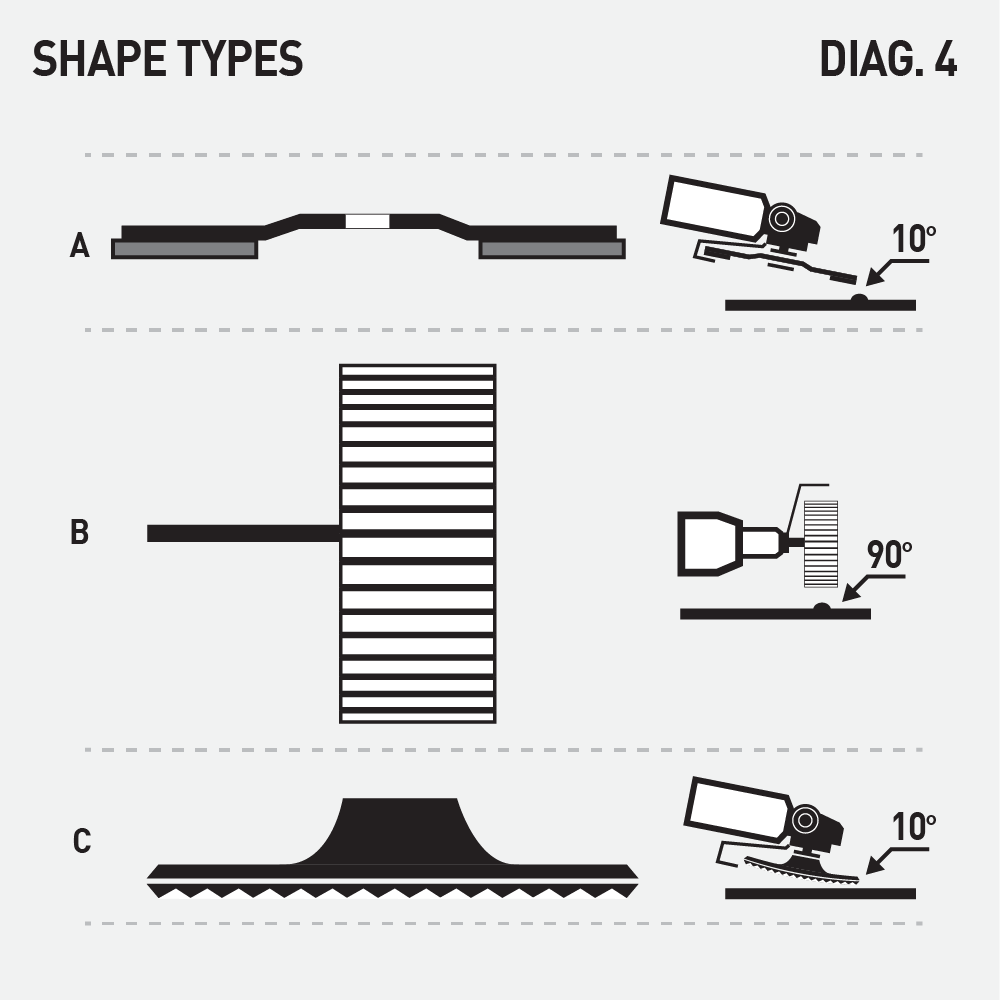

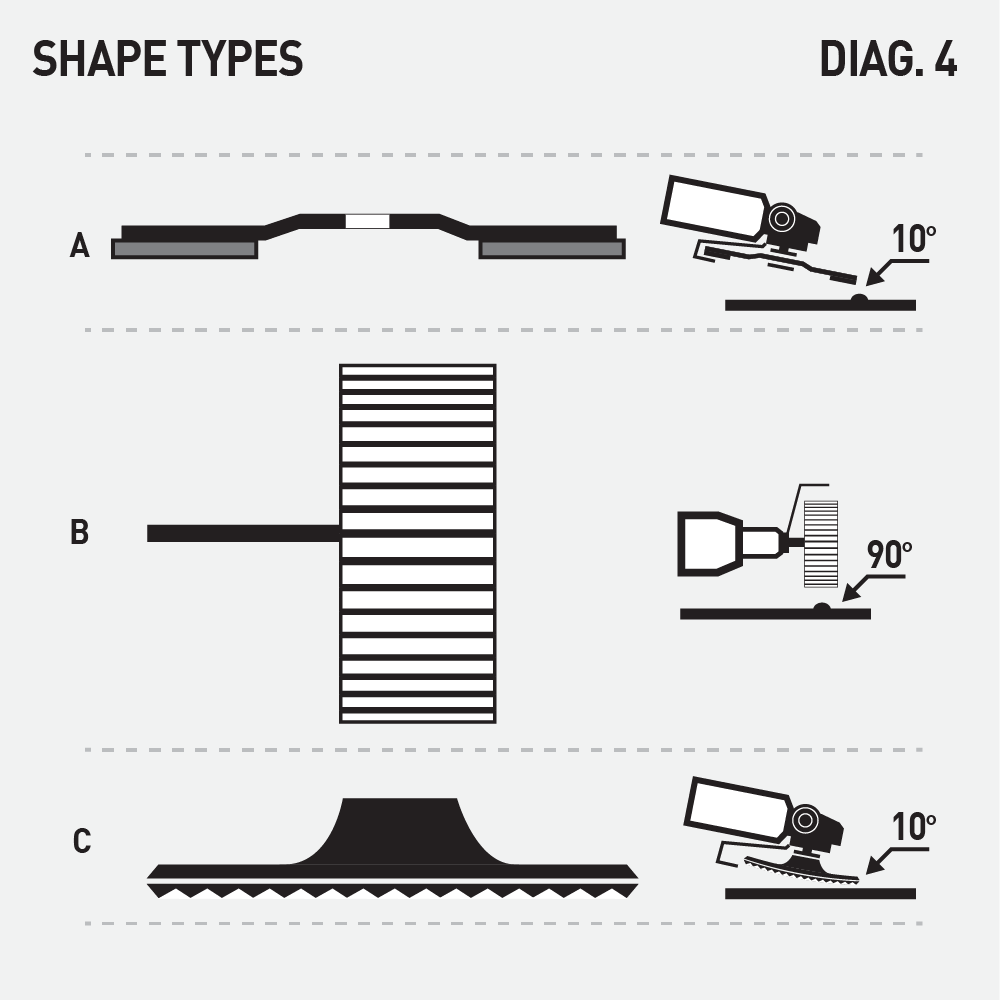

Flap discs: Use only with safety guard and at a 10° working angle (DIAG. 4A).

Flap wheels: check that the rotation direction corresponds to the one shown on the product.

Spindle mounted abrasive products: fit the spindle into the mandrel minimizing the protruding part and verify the rotation direction (DIAG.4B).

Fibre discs: use only with safety guard and suitable backing pad and clamping flange. The disc must protrude the backing pad by at least 2 mm; use at a 10° working angle (DIAG. 4C).

Sanding discs: use only with suitable backing pad and right fixing, Velcro/PSA. The disc must protrude the backing pad by at least 2 mm; use at a 5-10° working angle (DIAG. 4C).

Linishing belts: use only with safety guard. Do not touch the belt while moving. Store the belts hanged to drums of 50mm of minimum diameter. Do not damage the belt with sharp-edged pieces

Need assistance?

Need assistance?