Why Osprey Boats love Bora9 fibre discs (and you should too!)

Osprey Boats, Nelson - case study

'It sped up our process by 50%. We’ve gone from a 4 step process to a 2 step to get the same result.'

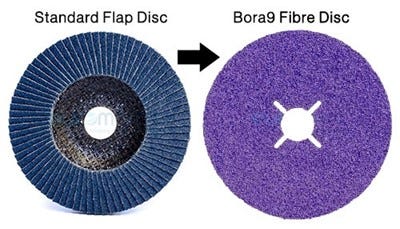

Matt from Osprey Boats in Nelson tells us why they switched from standard flap discs to Bora9 fibre discs for fabricating their custom built aluminium boats!

Tell us a bit about Osprey Boats...

Osprey are aluminium boat manufacturers located in sunny Nelson, New Zealand. They build custom aluminium boats, fishing boats, family boats, pontoon & recreational boats which are all fast growing in popularity!

Can you tell us a bit about your use of fibre discs?

We used to use coarse 40 grit flap discs on a lot of our boats for grinding back the welds. It used to be a 4 step process to get it to a finish we were happy with, and since we’ve changed to these discs [Bora9] from Euromarc, it’s now only a 2 step process to get the same results. So it’s beat our productivity by half. Plus they last longer, so we’re actually getting twice as much use out of each disc.

Why did you decide to give Bora9 a go?

A lot of people, if there’s nothing broken they don’t fix it. But there’s always something better. With us, there wasn’t anything broken, but we’ve improved our process. It’s just broadening our thinking, and thinking outside the square sometimes. There’s always another option out there. We’re always looking at ways we can improve.

You've been using Bora9 for a while now, how do you find it compared with standard flap discs?

It sped up our process by 50%. We’ve gone from a 4 step process to a 2 step to get the same result. I think it’s because they utilise a bigger surface area. We can use it on all contours of the boat, not just flat surfaces.

How would you compare them in terms of cost?

The fact they’re doing the work of 2 previous discs, and we’re getting twice as much work out of them, they’re cheaper.

They’re cost effective. Productivity’s gone up, and they’re doing the job of two previous discs.

Is there anything else you'd say about your experience with Euromarc?

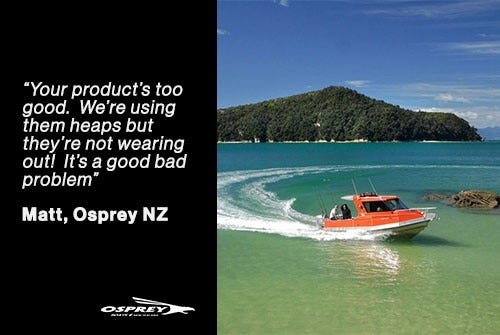

Your product’s too good. We’re using them heaps but they’re not wearing out! It’s a good bad problem.

With the gloves we were using, with our old stockist we used to go through a set of gloves every 3-5 weeks. With the Euromarc ones [Tig Max Welding Glove] we are replacing them every 3-5 months. I’d highly recommend using them. The Euromarc gloves are better in that they are seamless in the part between the thumb and the index finger. The old ones we used to have had a seam that gets hot when welding, or if you’re holding something hot or sharp, and it used to wear. So since we’ve gone to those [Tig Max Welding Glove], and I think it’s a slightly different material, compared to what we used before, these have proven to be better.

Need assistance?

Need assistance?