Operational & Safety Instructions for Wire Brushes

Like most things that involve power tools, there's a right and a wrong way to operate wire brushes and wheels if you want to stay safe and get the best results from your efforts. Believe it or not, wire brushes and wheels can generate dangerous situations and/or create accidents if not use correctly. Read carefully the following information to ensure the safe use of these products at all times.

Pre-Use Safety Procedures

Inspection

- Brushes should be carefully checked when removed from the original packaging. Do not use if there is any rust or damage seen. Check used brushes regularly.

Storage & Handling

- Store brushes in their original boxes.

- Wire brushes should not be exposed to heat, high humidity, acids, fumes or liquids that can result in deterioration of the wire filaments, leading to premature failure.

- Always check for any distortion of the brush fill that can cause imbalance and excessive vibration when the brush is run.

Machine Condition

- Proper machine maintenance is essential to keep them in a safe operating condition.

- Use adequate spindle diameter for the brush - do not use a brush that is larger than the machine is designed for.

- Brushing machines should have enough power to maintain the rated spindle speeds.

Safety

For safe operation of a wire brush with your power tool, the following safety practices must be followed to reduce the likelihood of you getting injured:

- Wear appropriate PPE including:

- Safety glasses/goggles and face shields to prevent flying particles hitting your eyes or face.

- Head protection, heavy leather apron, safety shoes & tight fitting clothes.

- Level 4 or 5 hearing protection such as earplugs or earmuffs

- Wear protective gloves that fully cover hands and wrists.

- Protect the respiratory tract: use respiratory masks with P3 or ABEK filters, or welding helmets with PAPR.

- Observe all speed restrictions indicated on the brushes & packaging. Do not exceed max RPM under any circumstances.

- Keep all machine guards in place.

- Do not use deteriorated brushes.

- Oxidation or any other chemical alteration in the wire may cause malfunctioning.

- Store brushes in their original packaging, in a clean and dry location protected from dust, humidity and other environmental effects.

Wire Brush Operational Guide

Brushing Pressure

Brushing pressure affects the quality of work as well as the brush life. Brushes should always be operated at the highest practical speed, with the lightest amount of pressure allowing the tips of the wire to do the work. Excessive pressure will bend the filaments resulting in a wiping action, rather than a cutting action. It also causes undue flexing of the filament, which will lead to premature breaking of the wire - shortening the useful life of the brush.

RPM

The power tool speed influences the performance of the brush and the safety of the operator. If the load speed marked on the power tool is higher than the brush maximum RPM, do not mount the brush. maximum RPM are indicated on the brush side plates, and should never be exceeded. These are the maximum RPM the brush can run with no work applied (spinning free). It is merely a safety indication for the user - not the recommended operating speed.

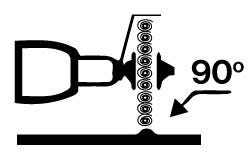

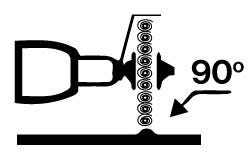

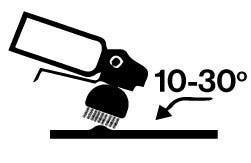

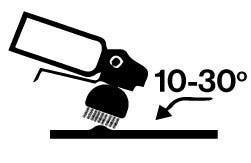

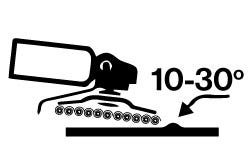

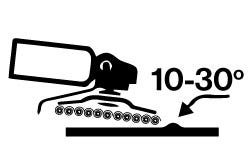

Working Angles

Wire wheels and brushes should be used on an angle to the work piece. The optimal angle will depend on the brush characteristics, the power tool being used, and the application. Further to this, the brushing pressure and technique will impact the outcome. Here is a general guide:

Twist Knot Wire Wheel Brushes

Wire Cup Brushes

Twist Knot Bevel Brushes

Need assistance?

Need assistance?