Assessing Auto-Darkening Welding Helmets: Features to Look Out For

Not all auto-darkening helmets are created equal. They range in quality from basic models for hobby welders to advanced options for professionals welding all day, every day. Depending on your welding needs, the features you prioritize will vary. Here’s what to consider when choosing the right auto-darkening welding helmet for you.

Type of Shade

Fixed or Variable?

A fixed shade auto-darkening helmet will sense an arc and darken to a fixed #10 shade. This 2-in-1 lens setup allows you to switch between clear and shade #10 lenses without manual adjustments. Fixed shade helmets are ideal for welders using consistent processes, materials, and thicknesses.

A variable shade helmet offers a range of shades, often from #9 to #13, automatically adjusting based on the arc’s brightness. This is perfect for welders who work with varying processes, materials, and amperages.

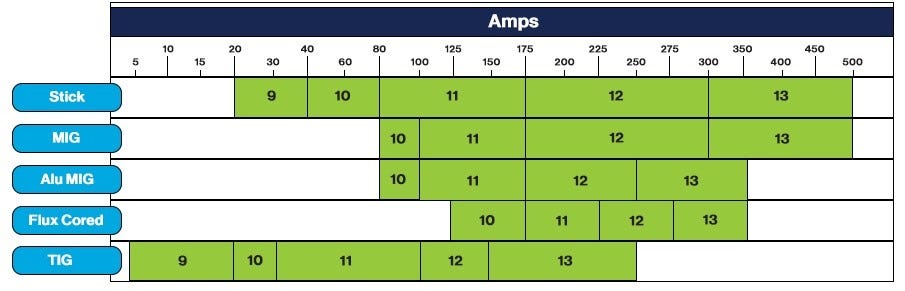

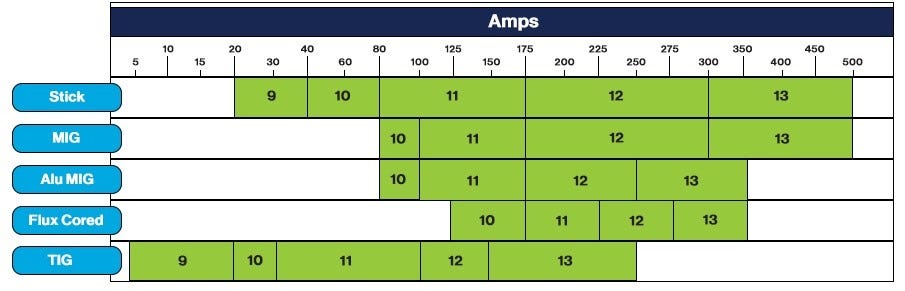

Shade Guide for Welding Processes

Below is a general guide to help you choose the right shade for different amperages and welding methods.

Lens Reaction Time

The speed at which the lens transitions from light to dark is crucial. Faster reaction times mean better eye protection and less fatigue. Entry-level lenses often react at 1/3,600 of a second, while professional-grade lenses can respond as quickly as 1/20,000 of a second. Welders who spend long hours at their craft will benefit from faster lenses, reducing the cumulative effects of arc light exposure.

Auto-darkening lens quality

To cut to the chase, if you want the best quality lens, you're looking for a lens with a 1/1/1/1 optical rating. This is the best you can get.

What does it mean? Well optical ratings are based on 4 criteria as described below. Each criteria is given a rating of 1-3, with 1 being the best and 3 the worst:

- Accuracy of vision (1/X/X/X): This rates how distorted the image is when you look at it through a welding helmet lens. A rating of 3 would be like looking through rippled water, and 1 would be clear and crisp.

- Diffusion of light (X/1/X/X): Rates the lens for any manufacturing impurities in the cartridge’s glass. A rating of 1 is clear, defect free and uniform.

- Variations in luminous transmittance (X/X/1/X): This rates the lens ability to adjust to different shades, and the consistency of the shade across different points of the lens surface. A rating of 1 indicates the lens provides a consistent shade across the entire surface.

- Luminous transmittance (X/X/X/1): This rates the clarity of the lens when viewed at an angle. It tests for a clear view without stretching, dark areas, or blurriness as the result of inconsistent shade.

Viewing Size

A larger viewing area can be beneficial for out-of-position welding. Some of the largest available view sizes measure 97x62 mm (3.82x2.44 inches) or more. Paired with LCD technology, these lenses provide a clear, natural view. The TECMEN TM1000 flip-front helmet even includes side-view lenses for a 150º field of vision.

Sensors

Arc sensors detect the arc light and adjust the lens. Entry-level helmets typically have 2 sensors, while advanced models can feature up to 4. Helmets with Intelligent Sensing Technology may require only 2 sensors while delivering top performance by distinguishing between welding arcs and other light sources.

Sensitivity Controls

Adjusting the brightness level that triggers lens darkening is crucial for professional welders, especially those working near others. Sensitivity controls prevent accidental darkening from nearby arcs and ensure consistent performance during low-amperage TIG welding.

Delay Controls

Delay controls let you adjust how long the lens stays dark after the arc stops. This is useful for:

-

Tack Welding: Short delays help reposition quickly.

-

High-Amperage Welding: Longer delays protect against residual harmful rays from hot metal.

Need assistance?

Need assistance?