- Home

- Abrasives

- Flap Discs

- Vortex Flap Disc

Need Help ?

NEED HELP?

No worries! We're here to help - here's how you can reach us...

- 0800 278 600

- sales@euromarc.co.nz

- Talk to us on live chat

Vortex Flap Disc

In stock

SKU

ZLVO

- loading...

Air cooling turbo backing & more abrasive, makes the cool finishing last longer.

Image

Product/Code

Size

Grit

Availability

Unit/Pack/Carton

Trade price

Qty

Size: 115xM14x2

Grit: 80g

Availability: In Stock

115xM14x2

80g

In Stock

- loading...

Forgot Password

Forgot your Password?

Air cooling turbo backing:

- The nylon support backing has wings inside the cavity which creates a vortex cooling effect.

- Turbo cooling reduces metal overheating and pitting while the operator is grinding, reducing blemishes and heat marks on the visual look of the metal.

- Cooling off the abrasive prolongs the zirconium grain, resin and cloth.

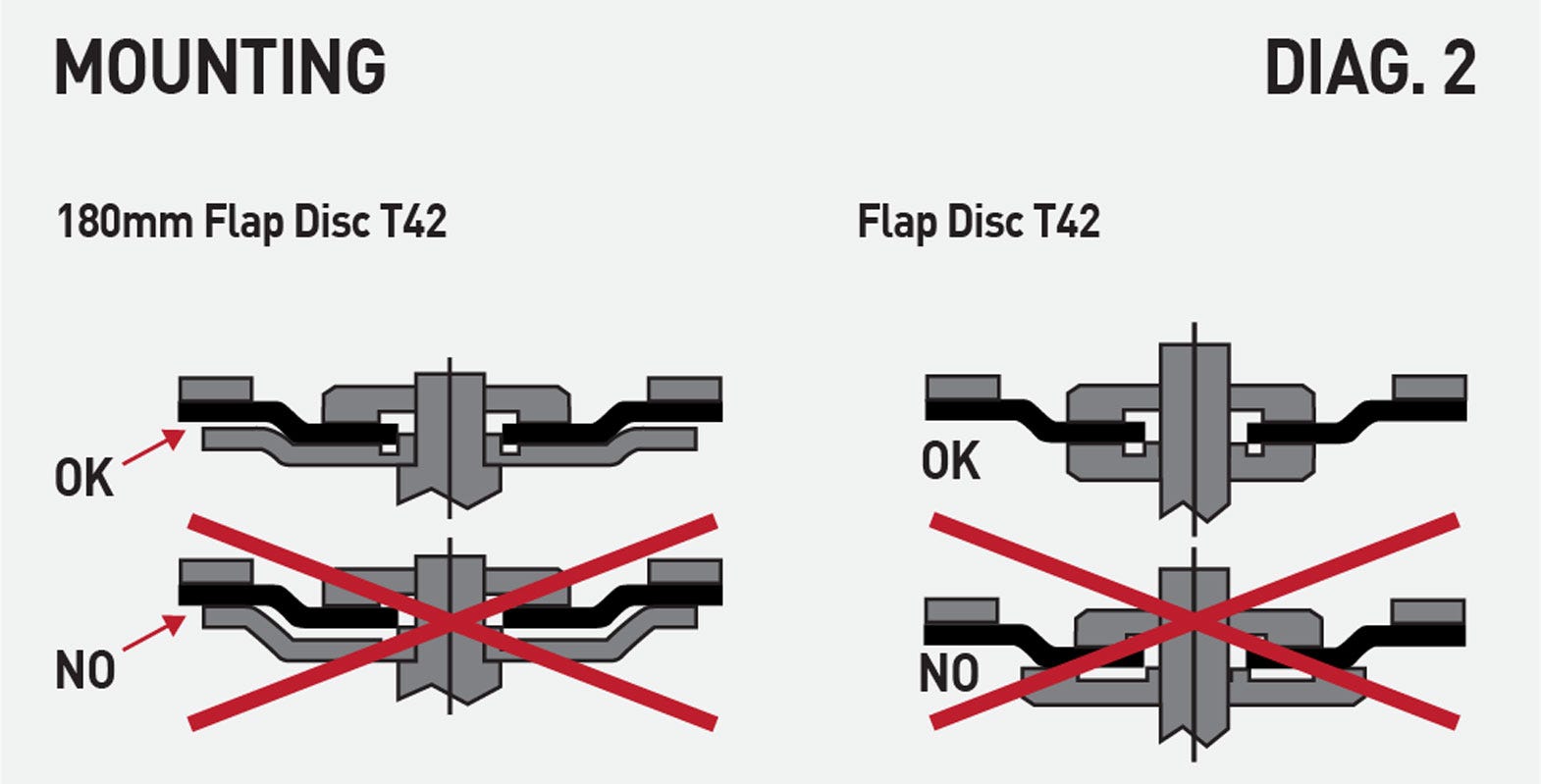

Easy fixing:

- The threaded bore allows the user to screw the disc to the grinder more quickly and easily.

- No need for clamping flanges and searching for the relevant keys for fixing.

More abrasive where you need it:

- The narrow and high crown layout is concentrated on the outer diameter of the disc, where the removal speed of the metal is higher.

- 30% more cloth, higher number of flaps and more angle allows more consistent removal capacity.

- Less abrasive cloth is remaining after the disc is finished compared to traditional discs, because the cloth is concentrated on the outer diameter of the disc.

Resources

-

Hustler Equipment - Cashflow Is Key For ProductionHustler Equipment, Hastings - case study 'The QUICKSTOCK... Read More

-

What happens if you use an expired cutting disc...Expiry dates on cutting discs are not like the expiry dates... Read More

-

Wire Brushes Troubleshooting GuideThere are a few common reasons your brushing application... Read More

-

Operating and safety instructions for bonded and reinforced abrasives (cutting and grinding discs)Cutting and grinding discsAbrasive discs can generate... Read More

-

Velvet Steel Found The Ultimate Sanding Discs With Bora1Velvet Steel Ltd, Wellington - case study 'It’s more... Read More

Other products you may like

*NEW* Ceramic grain, Flat nylon backing. Extra large flaps, for fast removal, even finishing and longevity.

*BEST SELLER* Standard conical shape with zirconia cloth, best for contoured & edge work.

125xM14x2 centre to fit directly onto grinders, premium cloth for a consistent finish. 20mm wide.

For less line marks from the side, non-woven for blending or satin finishing large areas.

Your web browser (Internet Explorer) is out of date. Update your browser for more security, speed and the best experience on this site.

Need Help ?

NEED HELP?

No worries! We're here to help - here's how you can reach us...

- 0800 278 600

- sales@euromarc.co.nz

- Talk to us on live chat

© 2023 Euromarc Industries. All rights reserved

Need assistance?

Need assistance?