All you need to know about PPE for pickling paste

Pickling paste is a well known product used for post weld cleaning amongst stainless steel engineers. For a long time pickling acid was the only way to achieve a truly clean result. Now, due to its widespread routine usage, the dangers of pickling paste and high importance of wearing personal protective equipment (PPE) are often overlooked...

Why is safety equipment important when handling pickling paste?

Pickling pastes are made up of a combination of hydrofluoric and nitric acids which can be extremely dangerous when handled incorrectly. Health issues identified when using pickling paste include:

- Contact with skin and eyes may cause severe damage without rapid first aid.

- Inhalation of spray may cause irritation and severe damage to the respiratory tract.

- Ingestion will lead to damage of the GI tract and is toxic if swallowed.

Some of these issues may not even be noticed until long after serious damage has been done. Since pickling paste has been a standard feature in many workshops, health and safety issues surrounding the substance can often be overlooked by employers when conducting checks. Read more on Worksafe compliance here: How To Keep Up With Worksafe With Pickling Paste

The two ways to avoid these serious health risks are:

- Ensure strict hazardous substance procedures are followed including wearing PPE; or

- Use an alternative method of weld cleaning, such as electrochemical cleaning

What safety gear is required for handling pickling paste?

If you, or any of your staff are using pickling paste it is essential the following protective equipment is worn at a minimum:

Respiratory

Gas mask with chlorine filter (grey) & dust filter P2 - A gas mask with filters is essential to protect the user from breathing in spray or fumes from the pickling paste causing throat irritation and severe respitory tract damage. Make sure the dust filter has a P2 rating which will provide protection against mechanically and thermally generated particles.

Hands

Acid resistant gloves - Any skin contact with pickling paste can cause severe acid burns causing destruction of deep tissue layers, including bone. Damage may not even be noticed until long after serious damage has been done. Any contact with pickling acid requires immediate first aid, and often a hospital visit. Ensure your hands are protected by thick, acid resistant PVC gloves. These gloves should preferably be long to protect both hands and forearms.

Eyes

Full-face shield & goggles - The diluted hydrofluoric acid in pickling paste can cause irreparable damage to your eyes, so it is important to wear googles/glasses that provide a snug fit and preferably a face seal. A full face shield should also be worn to prevent splashes hitting your face.

Body

Rubber acid resistant safety boots and acid resistant clothes/overalls - As above it is essential skin is protected from exposure to pickling paste to avoid serious burns. Clothing worn while handling pickling acid should be removed and washed prior to commencing work in other areas of the workshop to avoid contamination.

For more information on precautions that must be taken when handling pickling paste read How To Keep Up With Worksafe With Pickling Paste

What's the alternative to pickling paste?

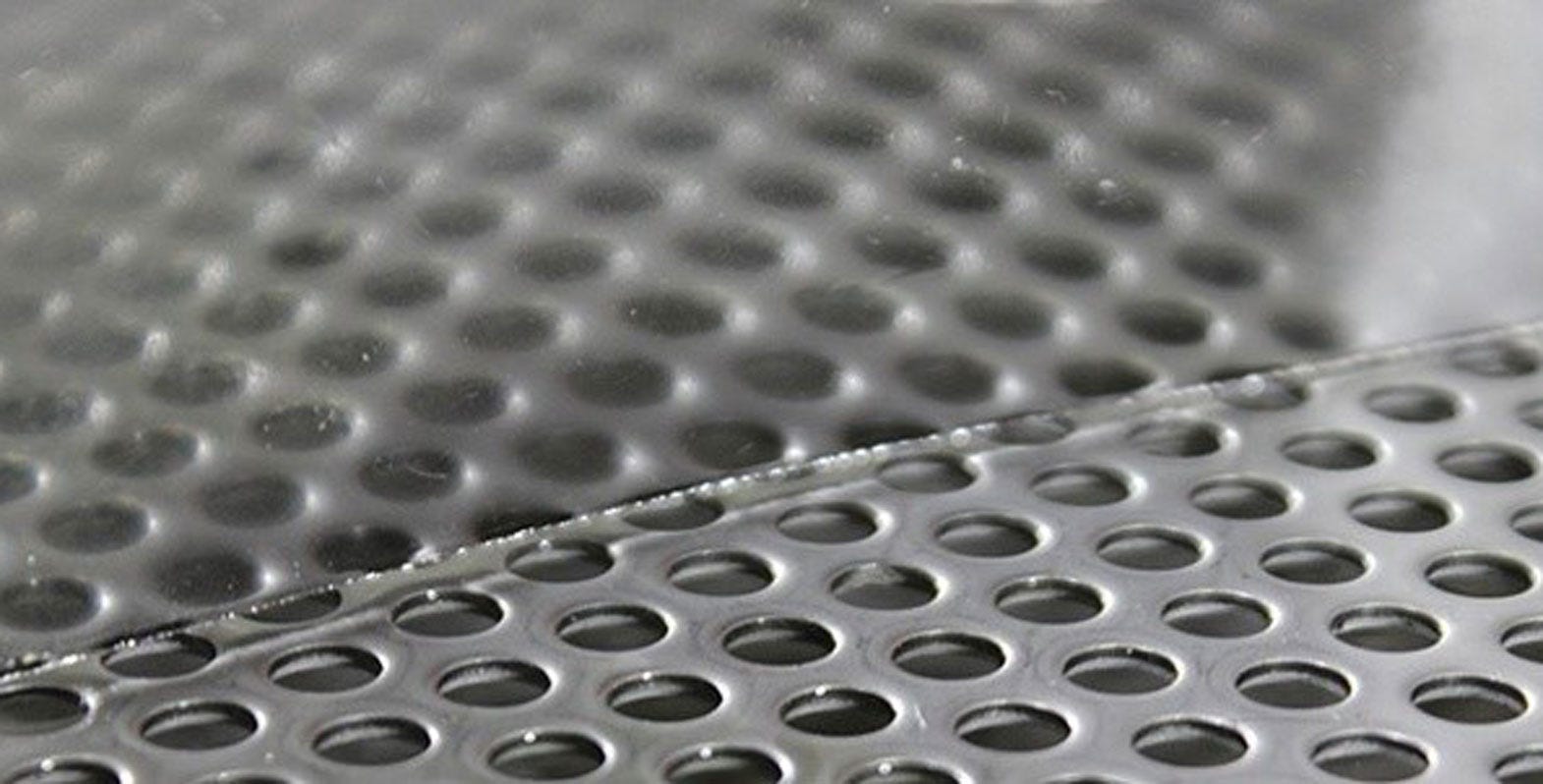

The best alternative to pickling paste is an electrochemical or electrolytic cleaning system. These systems have the same benefits of pickling paste in that they completely remove any contaminants on the metal surface and are able to reach all the nooks and crannies, however they also have some other benefits.....

A good quality electro-cleaner is:

- Safer to use than pickling paste, utilising a mild chemical solution paired with an electric currant.

- Faster than pickling paste - the system should clean the weld in a matter of seconds.

- Easier to use than pickling paste - quick set up, no mess, and hassle free clean up.

Electrochemical cleaning should restore the stainless steel back to its original finish, and studies suggest that the electrochemical cleaning method, when applied to a weld, can restore and even improve its corrosion resistance. The mild chemicals used mean the system can be used anywhere in the workshop and there is no need to pack on all the PPE like when you use pickling acid. For a more detailed explanation of how electrochemical cleaning works you can read our article here: What You Need To Kno bout Elelctrochemical Weld Cleaning Systems For Stainless Steel

Need assistance?

Need assistance?