Category:

All

-

Continuous Business Improvement

- 6

- 5

-

QUICKSKILL Training Academy

- 5

-

Case Studies

- 6

- 14

- 7

- 1

- 31

-

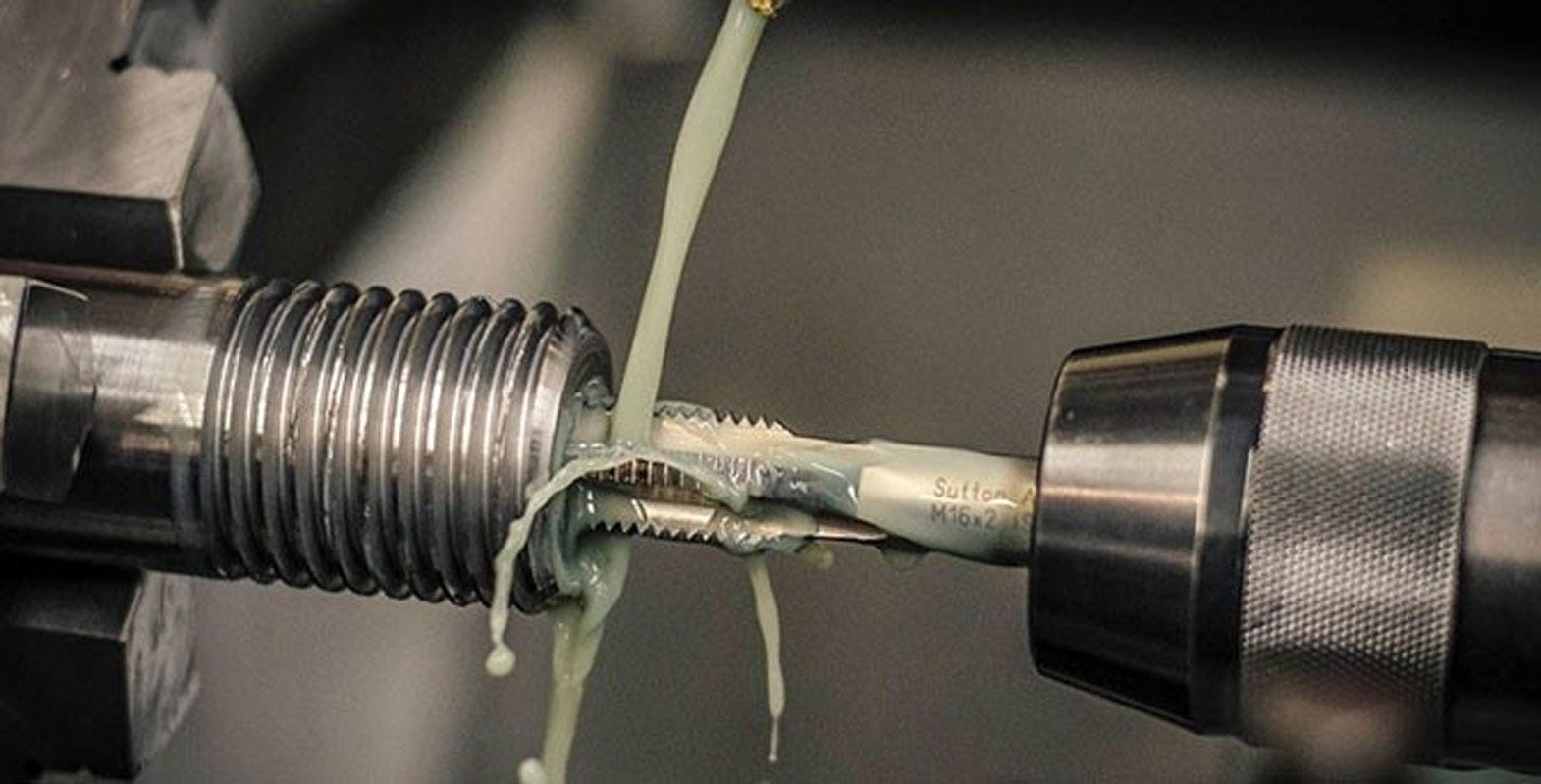

Metal Cutting / Removal / Finishing

- 5

- 6

- 5

- 17

- 10

- 4

-

Safety

- 62

- 7

- 9

- 4

- 2

- 9

- 35

- 17

-

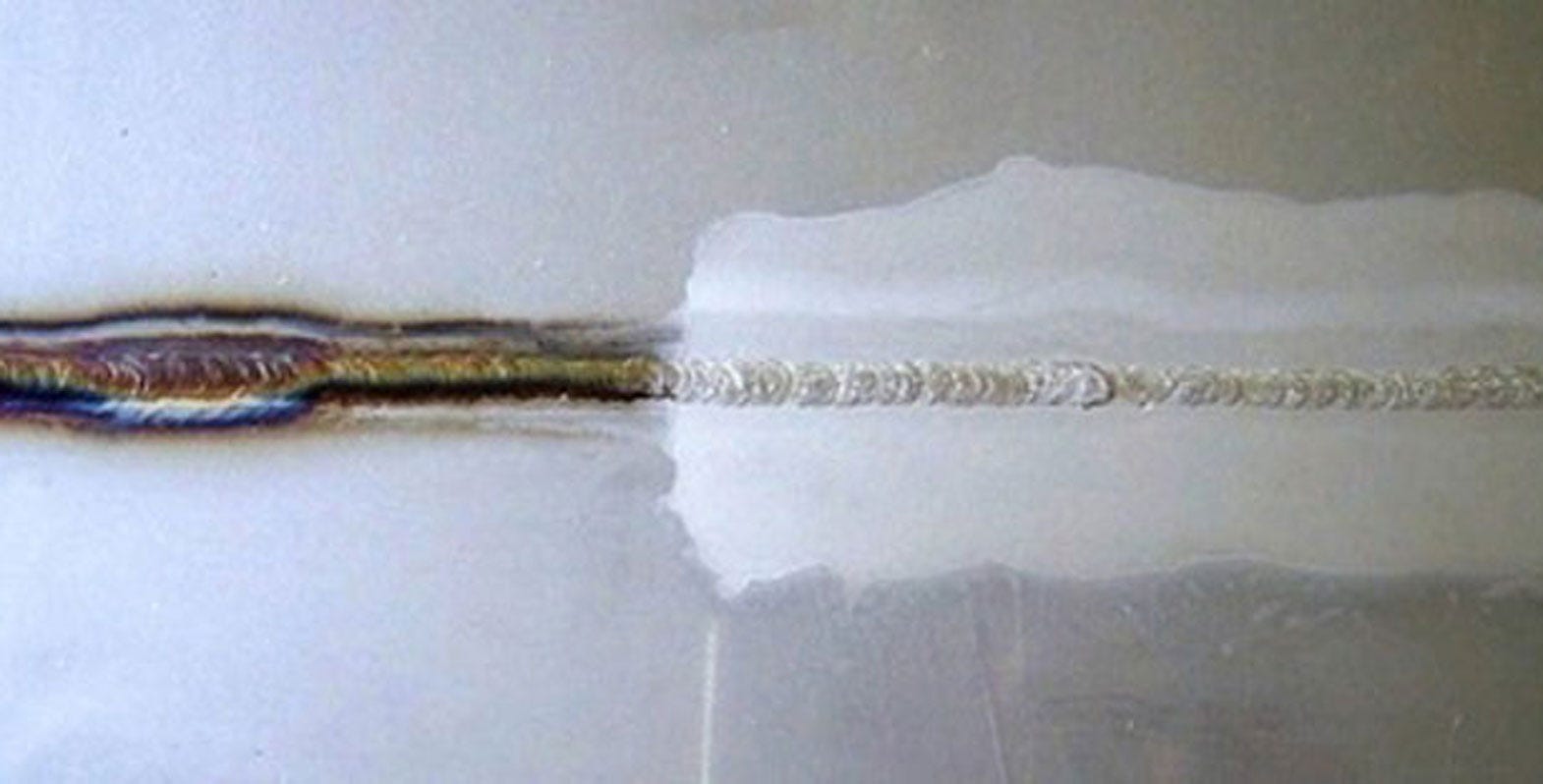

Weld Cleaning

- 6

- 4

- 8

- 5

Need assistance?

Need assistance?