Why QUICKSTOCK Made Good Sense For Total Stockcrates

Total Stockcrates, Palmerston North - Success Story

‘It’s added to our efficiency. It’s also improved our cash flow situation.'

We talk with Robin Fellingham, director at Total Stock Crates about how QUICKSTOCK just made sense for his business…

Tell us a bit about Total Stockcrates...

We build stock crates for sheep and cattle trucks, we have customers from Invercargill to Kaitaia. 20 years ago, myself and 4 others walked into an empty shed and we built the work benches. We now employ 14 guys on the floor and 3 years ago we built our own workshop – so we’ve come quite a long way in 20 years.

How did you manage consumable stock inventory before QUICKSTOCK?

Before QuickStock we didn’t really have a way of managing our stock, we just kind of coped. People would come to me and say “we’ve run out of something” rather than coming and saying “we’re running out of something”. That took somebody off the shop floor to come and tell me, it took somebody off the tools because they didn’t have the gear they needed. It took me away from my role as the key decision maker to run around trying to find stuff in a hurry. The downside of that was we lost a lot of productivity. We lost a lot of my concentration on what I should have been concentrating on. Rather than working on the business I was trying to patch holes in the business.

What led you to exploring your options in how you managed consumable stock inventory?

We had a good working relationship with Euromarc. A relationship based on mutual respect and understanding. A suggestion was made by the team at Euromarc that we’d look at this, and it just made good sense.

What made you decide to give the QUICKSTOCK solution a go?

Having worked as a rep in the retail industry years ago, I had an idea of the importance of stock holding and the fact that the suppliers were often in the best position to manage your stock. They have nothing to gain by overstocking me, and everything to gain from looking after me properly. I figured it was a no risk option we needed to explore.

Were there any hurdles with getting used to QUICKSTOCK?

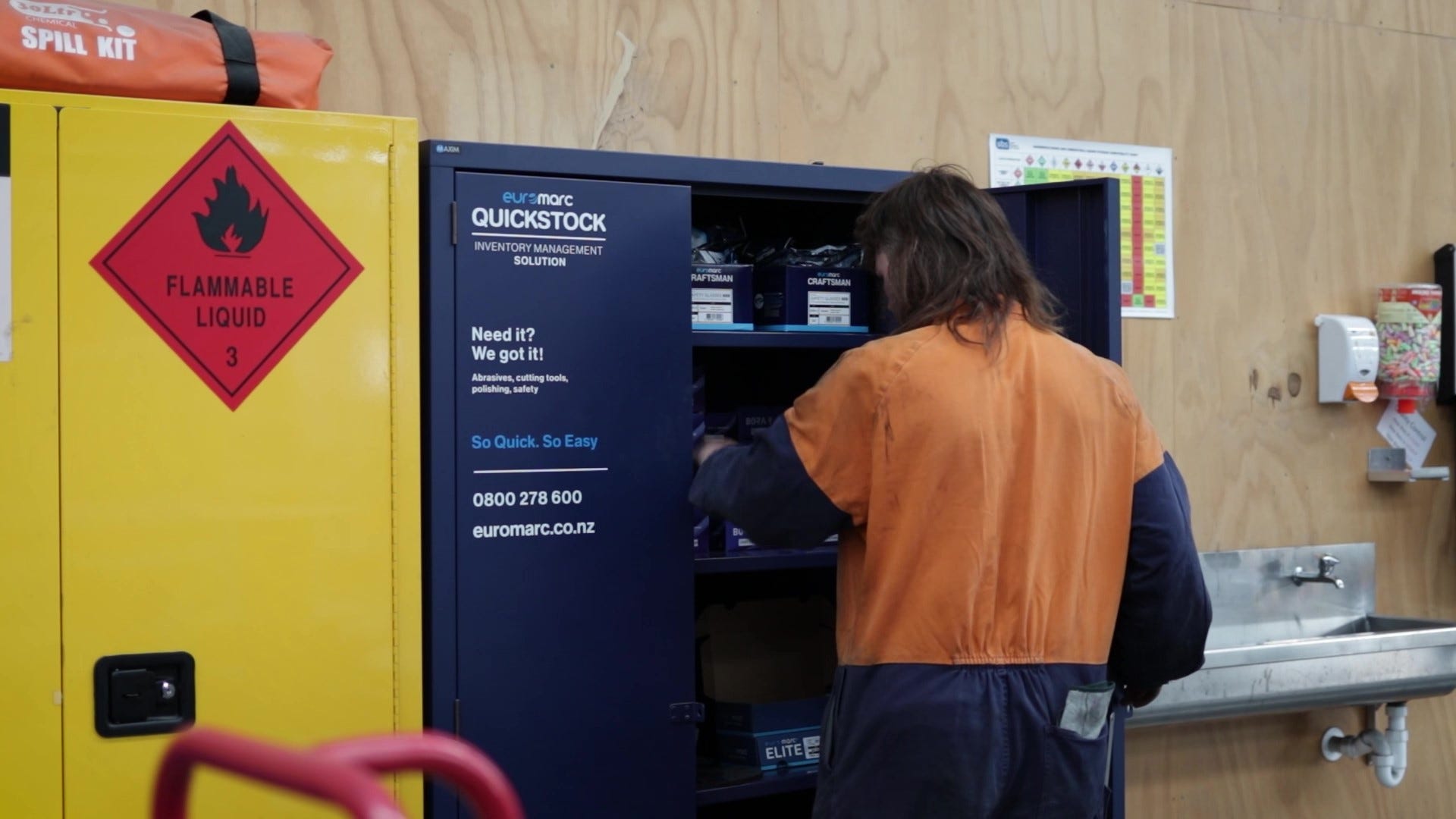

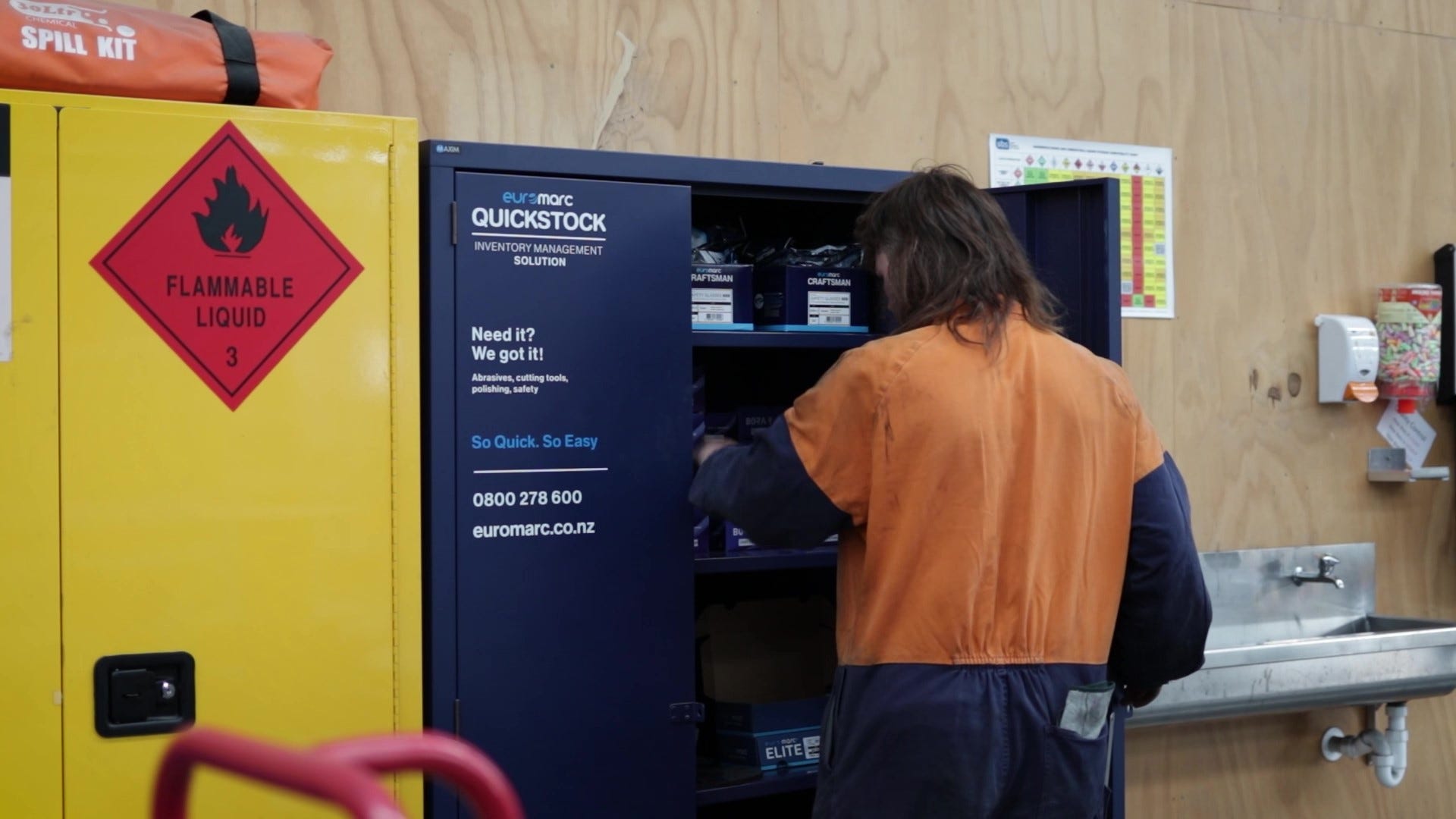

There were really no hurdles in getting used to using the QuickStock system. My guys were delighted that they didn’t have to come chase me, they just had to go to the cupboard to get what they needed, and they could go back to work. It’s relieved stress on me, and it’s increased productivity on the floor.

Some of the challenges we faced were running out of stock, or low on stock. No one would say anything because it was all free-for-all. QuickStock has made that a lot better. The number one benefit is we don’t have to worry about it, it just looks after itself. Because it’s always in stock, the guys aren’t having to find someone to say we’re out of stock. It keeps them on task, and on the job.'

– Troy Hill, Production Manager

How would you say QUICKSTOCK has improved your business?

QuickStock has improved our business in a number of ways. It’s added to our efficiency. It’s also improved our cash flow situation. We work on large capital items. Stock crates are not something you knock out in a day, and half a dozen small delays in a month can make the difference between getting paid this month or getting paid next month for the finished item. So that makes a real big difference to the smile on my bank managers face.

Would you recommend the QUICKSTOCK solution to other engineering companies?

I would recommend QuickStock to any engineering company that’s looking to improve its efficiency, improve its cashflow, and just basically take a whole lot of stress out of managing consumables.

Need assistance?

Need assistance?