What your boss wants you to know about mounting cutting & grinding discs safely

Need to know how to change a cutting or grinding disc without damaging yourself, the disc or your machine? Find the right and wrong ways of changing discs with images below...

Changing the disc

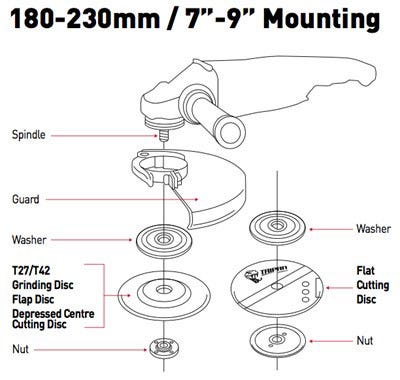

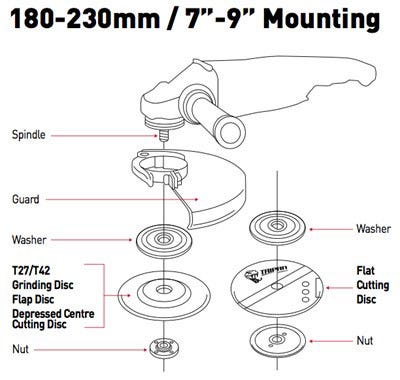

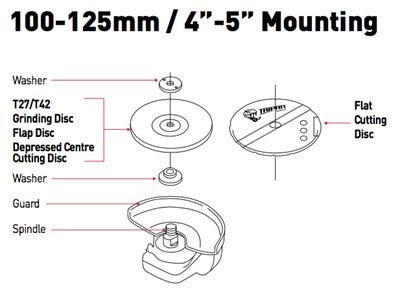

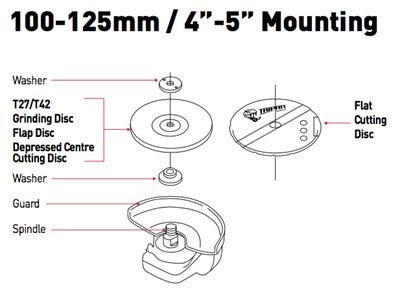

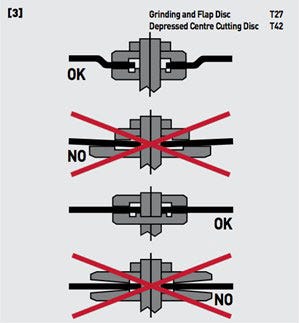

Mounting a cutting or grinding disc should be carried out according to instructions provided by both abrasive disc and machine manufacturer. In particular:

- Make sure flanges are flat and clean.

- Always use suitable flanges.

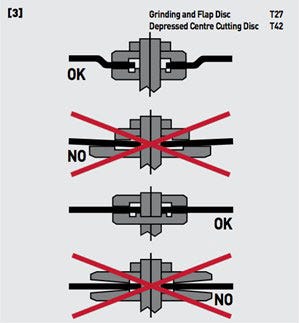

- Flanges must have the same diameter and same shape towards both faces of the disc. (Exception to the Raised Hub Flanges, Box [1]).

Inspecting the disc/wheel

- Before mounting your disc, make sure it is not cracked or damaged.

- Do not use wheels that are damaged or expired (we recommend using discs within 3 years of purchase).

- Carry out a sound check by striking one side of the disc with a non metallic object (screwdriver handle). If the sound is damp and not clear, reject the wheel.

- Do not use wheels that were exposed to too high/too low temperatures/humidity or that have been artificially or accidentally wet.

Inspecting the machine

- Check flanges, backing pads, support pivots and adapters.

- Make sure the grinder is suitable for the type of work to be made and that the wheel is adequate for the grinder.

- Always use with suitable safety guard, and always direct the open part of the safety guard to a direction opposite to the operator.

- Keep machines in an efficient state.

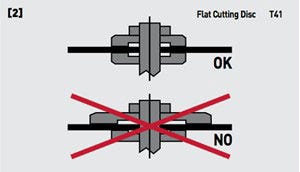

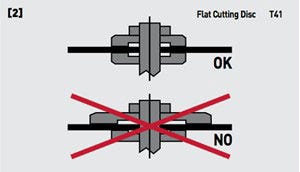

Clamping the flanges

- Make sure the flanges are flat, clean and smooth.

- Always use suitable flanges - Flanges must have the same diameter and the same shape (recesses) towards both faces of the wheel. Make an exception for the raised hub flanges.

Need assistance?

Need assistance?